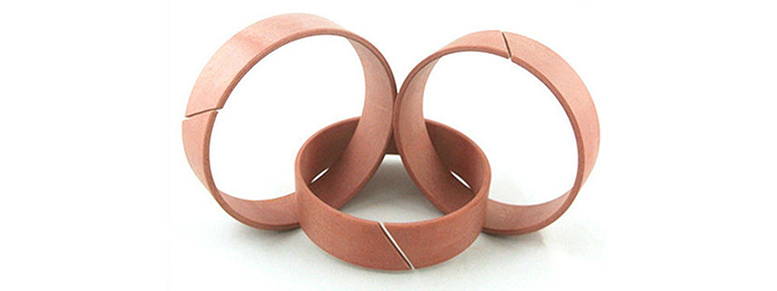

GUIDE RINGS AND WEAR BANDS.

What Are Guide Rings And Wear Bands

Guide Rings and Wear Bands are both important components used in mechanical systems, particularly in hydraulic and pneumatic applications. Here’s a closer look at each:

Guide Rings

– Purpose: Guide rings are primarily used to ensure proper alignment and guidance of moving parts, such as pistons within cylinders.

– Functionality: They help prevent misalignment, reduce friction, and minimize wear on seals and other components.

– Materials: Typically made from materials like nylon, polyurethane, or other low-friction materials to withstand wear and provide smooth operation.

– Applications: Common in hydraulic cylinders, pneumatic actuators, and machinery where precise movement is essential.

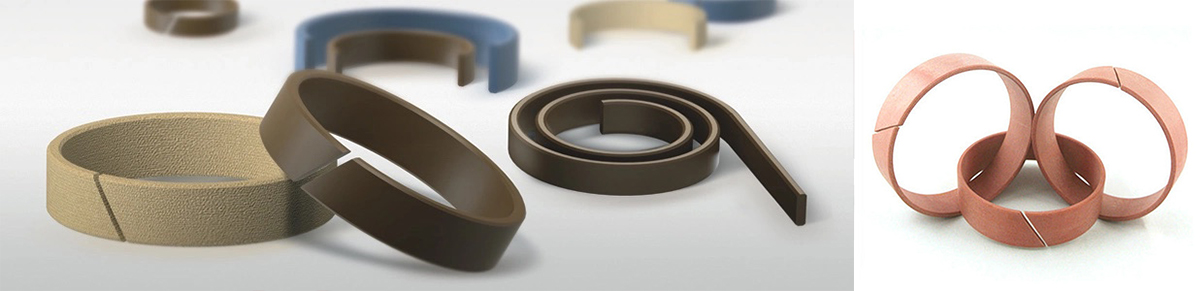

Wear Bands

– Purpose: Wear bands protect the surfaces of moving components from abrasion and wear.

– Functionality: They act as sacrificial surfaces that absorb wear, preventing damage to the underlying components. Wear bands help maintain performance by reducing friction and extending the life of the assembly.

– Materials: Usually made from tough plastics or composites like nylon or polyurethane, designed for high wear resistance.

– Applications: Found in similar applications as guide rings, including hydraulic and pneumatic systems, pumps, and various industrial machinery.

Key Differences

– Primary Role: Guide rings focus on alignment and guiding movement, while wear bands protect surfaces from wear and abrasion.

– Placement: Guide rings are typically installed around the outside of a moving part, whereas wear bands may be positioned on the inside or outside to absorb wear.

Both components are crucial for enhancing mechanical systems’ efficiency, longevity, and reliability. They often work together to ensure smooth operation in demanding environments.

Functions Of Guide Rings

Guide rings are components used in various mechanical and hydraulic systems to control the movement of other parts, typically within cylinders or pistons. They serve several important functions:

1. Alignment: Guide rings help maintain the proper alignment of moving components, ensuring smooth operation and reducing wear.

2. Wear Resistance: Often made from materials like polyurethane or nylon, guide rings provide a durable surface that can withstand friction and wear.

3. Load Distribution: They help distribute loads evenly across the surface, which can enhance the lifespan of the system.

4. Reduction of Friction: By providing a low-friction surface, guide rings can minimize energy loss and improve the efficiency of hydraulic or pneumatic systems.

5. Protection: They can protect seals from damage due to misalignment or excessive wear.

Guide rings are commonly found in hydraulic cylinders, pneumatic actuators, and various machinery applications where precise movement and alignment are critical.

Functions Of Wear Bands?

Wear bands, also known as wear rings or wear strips, are components designed to reduce wear and tear on moving parts in various machinery and equipment. They are typically made from durable materials such as nylon, polyurethane, or other engineered plastics. Here are some key features and functions of wear bands:

1. Protection: Wear bands protect the surfaces of components, such as pistons or cylinders, from abrasion and damage due to friction.

2. Friction Reduction: They provide a low-friction surface that helps to minimize energy loss and enhance the efficiency of moving parts.

3. Load Distribution: Wear bands help distribute loads evenly across surfaces, reducing stress and extending the lifespan of the components.

4. Easy Replacement: Since wear bands are often subject to wear themselves, they can be easily replaced without needing to replace the entire assembly.

5. Applications: Commonly used in hydraulic and pneumatic systems, pumps, and various industrial machinery where parts move relative to each other.

By minimizing wear and maintaining operational efficiency, wear bands play a crucial role in the longevity and reliability of mechanical systems.