BACKUP RINGS

WHAT ARE BACKUP RINGS?

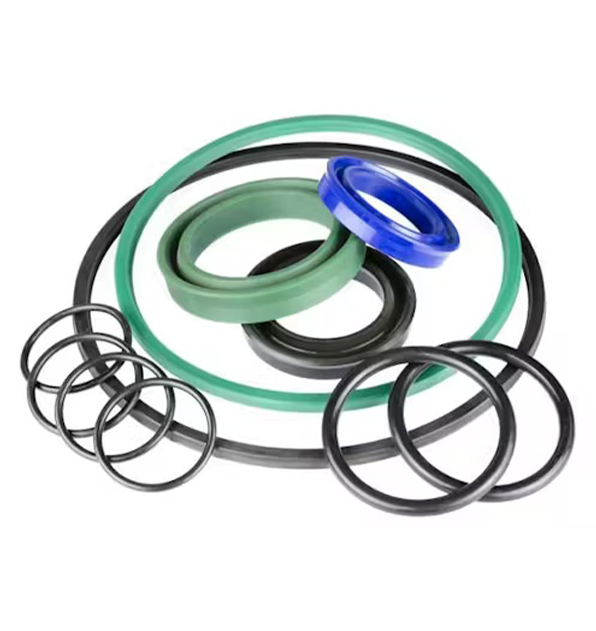

Backup rings are specialized sealing components used alongside O-rings and other types of seals to enhance their performance, particularly in high-pressure applications. Here’s a closer look at backup rings:

Purpose

- Prevent Extrusion: Backup rings are primarily designed to prevent the O-ring from extruding or deforming under high pressure, which can lead to seal failure.

- Improve Sealing Performance: They help maintain the shape and position of the O-ring, ensuring a better seal and longer service life.

Design

- Shape: Backup rings are typically flat or have a rectangular cross-section, and they can be made from materials like plastic, rubber, or metal, depending on the application.

- Material: Common materials include PTFE (Teflon), polyurethane, and various elastomers, chosen based on the operating environment and fluid compatibility.

TYPES OF BACKUP RINGS

Types

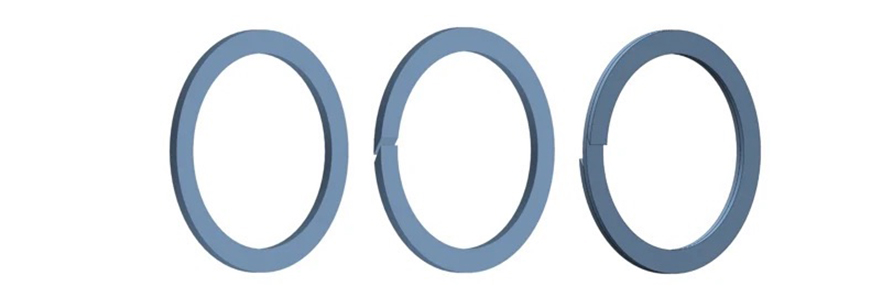

- Solid Backup Rings: Simple, flat rings that provide basic support for O-rings.

- Split Backup Rings: These have a gap, making installation easier and allowing for easier maintenance.

- Double Backup Rings: Used in applications where even higher pressure resistance is needed, often installed on both sides of the O-ring.

Applications

- Hydraulic Systems: Used in hydraulic cylinders and pumps to improve sealing under high pressure.

- Pneumatic Systems: Helps maintain effective sealing in pneumatic applications.

- Industrial Machinery: Commonly found in various machines where reliable sealing is critical.

Installation

Backup rings are usually placed in grooves alongside the O-ring. Proper installation is crucial to ensure that the backup ring performs effectively and extends the life of the primary seal.